Categories

Quick purchase

Please enter the article no. from our catalogue.

Welcome back!

Customer group: Guest

Products description

Optimill MH 25SPV -. Stable milling machine with electronic infinitely variable drive MH 25SPV with stepper motors and digital speed display DRO 5

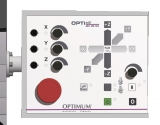

- User-friendly keypad

- Counterweight facilitates the adjustment of the Z-axis

- Variable speed control

- Simple tool change by a rocker

- Feed screws adjustable by adjustable spindle nuts

- All guides are ground and sichtgeschabt (oil pockets for lubrication)

- Precise processed

- Angular contact ball bearings in the axes, without clearance

pivotally Drill-mill head by ± 45 -

- Forward / reverse

- Height-adjustable screening grid with micro switch

- Sturdy dovetail precision ground and scraped with adjustable V-ledges

MH 25SPV: - Continuously adjustable feed in all axes

- Rapid traverse X / Y axis for quick positioning

- Digital 3-axis position display DRO 5

Touch Panel - Clear and easy to use

- Light-touch finger pressure sufficient to activate the touch function

Energy chain - wiring in an energy chain

Limit - for all three axes

The milling machine (frequency) corresponding to the standard DIN EN 55011: 2011-04 Class C2 - (used only in mixing and industrial areas)

Dimensions (length x width x height ) : 914 x 844 x 1,119 mm

Weight : 200 kg total power requirement: 2 kW

Drive motor power : 1.5 kW Spindle speed : 200 - 4,000 rpm 1

- User-friendly keypad

- Counterweight facilitates the adjustment of the Z-axis

- Variable speed control

- Simple tool change by a rocker

- Feed screws adjustable by adjustable spindle nuts

- All guides are ground and sichtgeschabt (oil pockets for lubrication)

- Precise processed

- Angular contact ball bearings in the axes, without clearance

pivotally Drill-mill head by ± 45 -

- Forward / reverse

- Height-adjustable screening grid with micro switch

- Sturdy dovetail precision ground and scraped with adjustable V-ledges

MH 25SPV: - Continuously adjustable feed in all axes

- Rapid traverse X / Y axis for quick positioning

- Digital 3-axis position display DRO 5

Touch Panel - Clear and easy to use

- Light-touch finger pressure sufficient to activate the touch function

Energy chain - wiring in an energy chain

Limit - for all three axes

The milling machine (frequency) corresponding to the standard DIN EN 55011: 2011-04 Class C2 - (used only in mixing and industrial areas)

Dimensions (length x width x height ) : 914 x 844 x 1,119 mm

Weight : 200 kg total power requirement: 2 kW

Drive motor power : 1.5 kW Spindle speed : 200 - 4,000 rpm 1