Please enter the article no. from our catalogue.

Products description

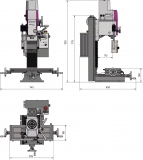

Optimill MH-22V Vario small drilling machine with electronically infinitely variable drive for the model builder

Technical specifications:

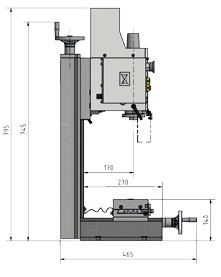

Length (product) 745 mm

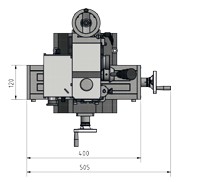

Width / depth (product) 650 mm

Height (product) 950 mm

Power drive motor 1.1 kW

Connection voltage 230 V

Phase (s) 1 Ph

Current type

Power frequency 50 Hz

Knife head size max. 52 mm

Shank cutter size max. 20 mm

Vertical spur projection 185 mm

Vertical spindle spindle adapter BT 20

Vertical spindle Speed range 90 - 3000 min-1

Vertical spindle Number of speed ranges 2

Horizontal milling length 700 mm

Horizontal milling width 180 mm

Distance vertical spindle - horizontal milling min. 370 mm

Distance vertical spindle - horizontal milling max. 370 mm

Horizontal milling table T-grooves Size 12 mm

Horizontal milling table T-slot spacing 63 mm

Travel distance X-axis manual 480 mm

Travel Y-axis manually 175 mm

Travel Z-axis manually 370 mm

Drilling capacity steel (S235JR) 18 mm

Continuous drilling capacity steel (S235JR) 16 mm

Vertical spindle Turning range milling head Z - X level 90 degrees

Vertical spindle Pinol diameter 60 mm

Vertical spindle Pinol stroke 50 mm

Weight (net) 116 kg

Robust drilling-milling machine with electronically continuously variable drive

Feed spindles can be adjusted without play by adjustable spindle nuts

Sturdy dovetail guide, precision ground and scraped with adjustable keel bars

EMC filter class B (use in private households)

All guides are ground and visually scaled (oil bags for lubrication)

Precisely processed

Double row angular contact ball bearings in the axes, play-free adjustable

Safety power supply in 24 volt version

Bellows as guide protection

Right / left run Drill milling head can be tilted by ± 900, for milling and drilling work in any angular position

Machine lamp

Height-adjustable protection screen with microswitch, against roving chips and parts, for the greatest possible protection of the user

Easy to read speed display and depth display, selectable mm / inch fine feed

Equipment details

Control electronics

Integrated relay control

engine

Two-stage transmission for a powerful transmission of engine power

Powerful DC motor with permanent current monitoring

Z-column and X-axis

Prepared groove for retrofitting the magnetic tapes

Control panel

User-friendly keyboard keyboard

Easy-to-read digital speed display

In summary

Emergency stop switch

Tapered roller bearing

High running accuracy ≤ 0.015 mm measured in the quill

pillar

Can be moved on both sides by 30 mm

When the head is tilted, longer travel distances and centered machining of the workpiece is possible

Rear with bore

Easy oiling of the trapezoid spindle or greases of the ball circulation spindles

Cross table

Solid

Precise surface treatment

With T-slots

Adjustable Keilleists

Adjustable by 3 handwheels

Adjustable end stops

Y axis

Prepared groove for retrofitting the magnetic tapes

Possible accessories

Universal substructure - Dimensions L x W x H: 420 x 340 x 800 mm

Item No. 3353000

Chip tray - dimensions L x W x H: 720 x 470 x 30 mm

Item No. 3352999

Digital position display DRO 5

Item No. 3383975

Factory assembly DRO 5

Item No. 9000420

Kegeldorn MK 2 / B16

- Operating tool

Data can still change!

Engine: 1.1 kW / 230V

Drilling capacity steel: 16 mm

(LxWxH): 745 x 650 x 950 mm