Categories

Quick purchase

Please enter the article no. from our catalogue.

Welcome back!

Customer group: Guest

New products

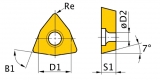

HM - replacement inserts ISO WNMG080408

ISO : WNMG080408

middle plate width ( D1 ) : 9,252 mm

Bore ( D2 ) : 3.81 mm

Angle ( B1 ) : 80 °

Height insert ( S1 ) : 4.76mm

Radius ( Re) : 0.8 mm

middle plate width ( D1 ) : 9,252 mm

Bore ( D2 ) : 3.81 mm

Angle ( B1 ) : 80 °

Height insert ( S1 ) : 4.76mm

Radius ( Re) : 0.8 mm

Shipping time: available immediately

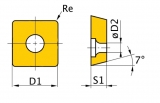

HM - replacement inserts ISO PSDNN3232P15

ISO : PSDNN3232P15

middle plate width ( D1 ) : 15.875 mm

Bore ( D2 ) : 6.35 mm

Angle ( B1 ) : 90 °

Height insert ( S1 ) : 6.35mm

Radius ( Re) : 0.8 mm

middle plate width ( D1 ) : 15.875 mm

Bore ( D2 ) : 6.35 mm

Angle ( B1 ) : 90 °

Height insert ( S1 ) : 6.35mm

Radius ( Re) : 0.8 mm

Shipping time: available immediately

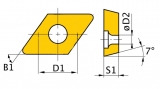

HM - replacement inserts ISO DNMG150408

Shipping time: available immediately

Clamping block set 20-05 clamping block set for lathes

1 Each clamping block SLTBN 20-05

- 1 piece Abstechdrehmeißel SLIH 26-3

- 1 piece Abstechdrehmeißel SLIH 26-4

- 5 pieces cutting GTN3 ( cutting width 3.1 mm )

- 5 pieces cutting GTN4 ( cutting width 4.1 mm )

- Aluminium

- 1 piece Abstechdrehmeißel SLIH 26-3

- 1 piece Abstechdrehmeißel SLIH 26-4

- 5 pieces cutting GTN3 ( cutting width 3.1 mm )

- 5 pieces cutting GTN4 ( cutting width 4.1 mm )

- Aluminium

Shipping time: available immediately

OptiTurn TH 4210D - Centre lathes

Length (product): 2025 mm

Width / depth (product): 915 mm

Height (product): 1615 mm

Weight (net): 1160 kg

Drive motor power: 4.5 kW

Power consumption: 4.6 kW

Total power consumption:

Voltage: 400 V

Phase (s): 3 Ph

Current: ~

Frequency: 50 Hz

Spindle taper: Camlock DIN ISO 702-2 Nr. 6

Spindle bore / bar passage diameter: 52 mm

Center height: 210 mm

Distance between centers: 1000 mm

Swing over machine bed: 420 mm

Swing in the bed gap: 590 mm

Swing over cross slide: 250 mm

Turning length in the bed gap: 260 mm

Bed width: 250 mm

Speed range: 45 - 1800 rpm 1

Number of speed ranges: 16 steps

X axis travel: 140 mm

Y axis: 230 mm

Tailstock: MK 4

Tailstock quill stroke: 120 mm

Tailstock quill diameter: 50 mm

Coolant system performance coolant pump: 100 W

Spindle taper: MK 6

Tool holder Seat height max .: 20 x 20 mm

Tool holder seat height with optional quick change tool:

Feed range longitudinal: 0,05 - 1,7 mm / rev

Number of feeds along: 17

Feed range plan: 0.025 to 0.85 mm / rev

Number of feed plan: 17

Pitch Metric: 0,2 - 14 mm / U

Number of pitches Metric: 39

Slope inches: 72-2 Gg / inch

Number of slopes inch: 45

Slope Diametral Pitch: 8-44

Number of slopes Diametral Pitch: 21

Slope module thread 0.3 - 3.5mm

Number of slopes module thread: 18

Width / depth (product): 915 mm

Height (product): 1615 mm

Weight (net): 1160 kg

Drive motor power: 4.5 kW

Power consumption: 4.6 kW

Total power consumption:

Voltage: 400 V

Phase (s): 3 Ph

Current: ~

Frequency: 50 Hz

Spindle taper: Camlock DIN ISO 702-2 Nr. 6

Spindle bore / bar passage diameter: 52 mm

Center height: 210 mm

Distance between centers: 1000 mm

Swing over machine bed: 420 mm

Swing in the bed gap: 590 mm

Swing over cross slide: 250 mm

Turning length in the bed gap: 260 mm

Bed width: 250 mm

Speed range: 45 - 1800 rpm 1

Number of speed ranges: 16 steps

X axis travel: 140 mm

Y axis: 230 mm

Tailstock: MK 4

Tailstock quill stroke: 120 mm

Tailstock quill diameter: 50 mm

Coolant system performance coolant pump: 100 W

Spindle taper: MK 6

Tool holder Seat height max .: 20 x 20 mm

Tool holder seat height with optional quick change tool:

Feed range longitudinal: 0,05 - 1,7 mm / rev

Number of feeds along: 17

Feed range plan: 0.025 to 0.85 mm / rev

Number of feed plan: 17

Pitch Metric: 0,2 - 14 mm / U

Number of pitches Metric: 39

Slope inches: 72-2 Gg / inch

Number of slopes inch: 45

Slope Diametral Pitch: 8-44

Number of slopes Diametral Pitch: 21

Slope module thread 0.3 - 3.5mm

Number of slopes module thread: 18

Shipping time: available immediately

OPTIturn TH 4210V

Length (product): 2025 mm

Width / depth (product): 915 mm

Height (product): 1615 mm

Weight (net): 1160 kg

Drive motor power: 4.5 kW

Power consumption: 4.6 kW

Total power consumption:

Voltage: 400 V

Phase (s): 3 Ph

Current: ~

Frequency: 50 Hz

Spindle taper: Camlock DIN ISO 702-2 Nr. 6

Spindle bore / bar passage diameter: 52 mm

Center height: 210 mm

Distance between centers: 1000 mm

Swing over machine bed: 420 mm

Swing in the bed gap: 590 mm

Swing over longitudinal slide:

Swing over cross slide: 250 mm

Turning length in the bed gap: 260 mm

Bed width: 250 mm

Speed range: 30 - 3000 min-1

Number of speed ranges: 2 stages

X axis travel: 140 mm

Y axis: 230 mm

Tailstock: MK 4

Tailstock quill stroke: 120 mm

Tailstock quill diameter: 50 mm

Coolant system performance coolant pump: 100 W

Spindle taper: MK 6

Tool holder Seat height max .: 20 x 20 mm

Controlling the speed control: electronically adjustable

Feed range longitudinal: 0,05 - 1,7 mm / rev

Number of feeds along: 17

Feed range plan: 0.025 to 0.85 mm / rev

Number of feed plan: 17

Pitch Metric: 0,2 - 14 mm / U

Number of pitches Metric: 39

Slope inches: 72-2 Gg / inch

Number of slopes inch: 45

Slope Diametral Pitch: 8-44

Number of slopes Diametral Pitch: 21

Slope module thread 0.3 - 3.5mm

Number of slopes module thread: 18

Width / depth (product): 915 mm

Height (product): 1615 mm

Weight (net): 1160 kg

Drive motor power: 4.5 kW

Power consumption: 4.6 kW

Total power consumption:

Voltage: 400 V

Phase (s): 3 Ph

Current: ~

Frequency: 50 Hz

Spindle taper: Camlock DIN ISO 702-2 Nr. 6

Spindle bore / bar passage diameter: 52 mm

Center height: 210 mm

Distance between centers: 1000 mm

Swing over machine bed: 420 mm

Swing in the bed gap: 590 mm

Swing over longitudinal slide:

Swing over cross slide: 250 mm

Turning length in the bed gap: 260 mm

Bed width: 250 mm

Speed range: 30 - 3000 min-1

Number of speed ranges: 2 stages

X axis travel: 140 mm

Y axis: 230 mm

Tailstock: MK 4

Tailstock quill stroke: 120 mm

Tailstock quill diameter: 50 mm

Coolant system performance coolant pump: 100 W

Spindle taper: MK 6

Tool holder Seat height max .: 20 x 20 mm

Controlling the speed control: electronically adjustable

Feed range longitudinal: 0,05 - 1,7 mm / rev

Number of feeds along: 17

Feed range plan: 0.025 to 0.85 mm / rev

Number of feed plan: 17

Pitch Metric: 0,2 - 14 mm / U

Number of pitches Metric: 39

Slope inches: 72-2 Gg / inch

Number of slopes inch: 45

Slope Diametral Pitch: 8-44

Number of slopes Diametral Pitch: 21

Slope module thread 0.3 - 3.5mm

Number of slopes module thread: 18

Shipping time: available immediately

OPTIturn TH 4215D

Length (product): 2525 mm

Width / depth (product): 915 mm

Height (product): 1615 mm

Weight (net): 1340 kg

Drive motor power: 4.5 kW

Power consumption: 4.6 kW

Voltage: 400 V

Phase (s): 3 Ph

Current: ~

Frequency: 50 Hz

Spindle taper: Camlock DIN ISO 702-2 Nr. 6

Spindle bore / bar passage diameter: 52 mm

Center height: 210 mm

Distance between centers: 1500 mm

Swing over machine bed: 420 mm

Swing in the bed gap: 590 mm

Swing over cross slide: 250 mm

Turning length in the bed gap: 260 mm

Bed width: 250 mm

Speed range: 45 - 1800 rpm 1

Number of speed ranges: 16 steps

X axis travel: 140 mm

Y axis: 230 mm

Tailstock: MK 4

Tailstock quill stroke: 120 mm

Tailstock quill diameter: 50 mm

Coolant system performance coolant pump: 100 W

Coolant system tank capacity:

Spindle taper: MK 6

Tool holder Seat height max .: 20 x 20 mm

Feed range longitudinal: 0,05 - 1,7 mm / rev

Number of feeds along: 17

Feed range plan: 0.025 to 0.85 mm / rev

Number of feed plan: 17

Pitch Metric: 0,2 - 14 mm / U

Number of pitches Metric: 39

Slope inches: 72-2 Gg / inch

Number of slopes inch: 45

Slope Diametral Pitch: 8-44

Number of slopes Diametral Pitch: 21

Slope module thread 0.3 - 3.5mm

Number of slopes module thread: 18

Width / depth (product): 915 mm

Height (product): 1615 mm

Weight (net): 1340 kg

Drive motor power: 4.5 kW

Power consumption: 4.6 kW

Voltage: 400 V

Phase (s): 3 Ph

Current: ~

Frequency: 50 Hz

Spindle taper: Camlock DIN ISO 702-2 Nr. 6

Spindle bore / bar passage diameter: 52 mm

Center height: 210 mm

Distance between centers: 1500 mm

Swing over machine bed: 420 mm

Swing in the bed gap: 590 mm

Swing over cross slide: 250 mm

Turning length in the bed gap: 260 mm

Bed width: 250 mm

Speed range: 45 - 1800 rpm 1

Number of speed ranges: 16 steps

X axis travel: 140 mm

Y axis: 230 mm

Tailstock: MK 4

Tailstock quill stroke: 120 mm

Tailstock quill diameter: 50 mm

Coolant system performance coolant pump: 100 W

Coolant system tank capacity:

Spindle taper: MK 6

Tool holder Seat height max .: 20 x 20 mm

Feed range longitudinal: 0,05 - 1,7 mm / rev

Number of feeds along: 17

Feed range plan: 0.025 to 0.85 mm / rev

Number of feed plan: 17

Pitch Metric: 0,2 - 14 mm / U

Number of pitches Metric: 39

Slope inches: 72-2 Gg / inch

Number of slopes inch: 45

Slope Diametral Pitch: 8-44

Number of slopes Diametral Pitch: 21

Slope module thread 0.3 - 3.5mm

Number of slopes module thread: 18

Shipping time: available immediately

OPTIturn TH 4610D

Electrical connection: 400 V / 3 Ph ~ 50 Hz

Total connected load: 5.8 kW

Capacity of the coolant pump: 100 W

Drive motor spindle: 5,5 KW

Spindle taper: MK 6

Spindle taper: Camlock DIN ISO 702-2 Nr. 6

Spindle bore, bar capacity: 58 mm

Quadruple tool holder Seat height: max. 25 x 25 mm

Center height: 230 mm

Distance between centers: 1000 mm

Swing over machine bed: 465 mm

Swing over cross slide: 270 mm

Turning Ø in the bed gap: 690 mm

Turning length in the bed gap: 240 mm

Bed width: 300 mm

Spindle speed: 25 - 2000 rpm 1

Number of steps: 12 steps

Traverse top slide: 125 mm

Traverse cross slide: 285 mm

Longitudinal feed in the range: 0.031 to 1.7 mm / rev 42 feeds

Cross feed in the range: 0.014 to 0.784 mm / rev 42 feeds

Pitch - Metric in the range 0.1 - 14 mm / rev 41 pitches

Pitch - inch in the range: 112-2 Gg / 1 41 pitches

Diametral pitch in the range: 4 - 112 50 Gewindegaenge

Module threads in the range: 0,1 - 7 34 module thread

Tailstock: MK 4

Tailstock quill diameter: 60 mm

Tailstock sleeve: 130 mm

Dimensions (L x W x H): 2.200 mm x 1.245 x 1.568 mm

Net weight: 1645 kg

Total connected load: 5.8 kW

Capacity of the coolant pump: 100 W

Drive motor spindle: 5,5 KW

Spindle taper: MK 6

Spindle taper: Camlock DIN ISO 702-2 Nr. 6

Spindle bore, bar capacity: 58 mm

Quadruple tool holder Seat height: max. 25 x 25 mm

Center height: 230 mm

Distance between centers: 1000 mm

Swing over machine bed: 465 mm

Swing over cross slide: 270 mm

Turning Ø in the bed gap: 690 mm

Turning length in the bed gap: 240 mm

Bed width: 300 mm

Spindle speed: 25 - 2000 rpm 1

Number of steps: 12 steps

Traverse top slide: 125 mm

Traverse cross slide: 285 mm

Longitudinal feed in the range: 0.031 to 1.7 mm / rev 42 feeds

Cross feed in the range: 0.014 to 0.784 mm / rev 42 feeds

Pitch - Metric in the range 0.1 - 14 mm / rev 41 pitches

Pitch - inch in the range: 112-2 Gg / 1 41 pitches

Diametral pitch in the range: 4 - 112 50 Gewindegaenge

Module threads in the range: 0,1 - 7 34 module thread

Tailstock: MK 4

Tailstock quill diameter: 60 mm

Tailstock sleeve: 130 mm

Dimensions (L x W x H): 2.200 mm x 1.245 x 1.568 mm

Net weight: 1645 kg

Shipping time: available immediately

Three-jaw chucks CS3C ø 250 mm Camlock DIN ISO 702-2 Nr . 6

Chucks steel

Camlock DIN 55029 Direct recording

Diameter: 250 mm

Through Hole : 78 mm

Height with jaws : 143 mm

Height without jaws : 89 mm

Speed : 3,500 min - 1

Camlock DIN 55029 Direct recording

Diameter: 250 mm

Through Hole : 78 mm

Height with jaws : 143 mm

Height without jaws : 89 mm

Speed : 3,500 min - 1

Shipping time: available immediately

Top jaw set , soft, unstepped for CS3C ø 250 mm Nr . 6 and Nr . 8

Camlock DIN ISO 702-2 Nos. 6 and CS3C ø 250 mm Camlock DIN ISO 702-2 Nr . 8

Shipping time: available immediately